Positive Displacement Downhole Sampler

PVT analysis of reservoir fluids is fundamental to reservoir management. Corrosion potential measurements (e.g., pressurized pH measurements in formation water), asphaltene deposits, and non-hydrocarbon constituents have the potential to have serious implications for manufacturing facility design, compatibility with pipeline transportation, retail product value, and maintenance costs of the refinery and deposit values in general. The lack of such data could easily pose a greater risk than is tolerated when deciding whether to conduct sampling and laboratory testing. The earlier one can understand reservoir fluid properties during field development, the better one can effectively and more cost-efficiently meet many challenges, including optimizing reservoir models, selecting completion materials and strategies, and designing process and production facilities.

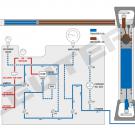

Since laboratory analyzes are only as good as the samples taken, truly representative samples of formation fluid under reservoir conditions must be taken. The Leutert Positive Displacement Downhole Sampler PDS delivers truly representative samples in unaltered condition. No separator is required at the well. The downhole fluid sampler is lowered into the wellbore on a slickline so that a sample of the fluid can be taken under the elevated pressure of the fluid column. Leutert downhole samplers can be operated in banks with up to eight tools. Each downhole sampler has its own clock, giving flexibility in deciding when and at what depth shall be sampled. Alternatively, Leutert downhole samplers can be operated with wireline or electric line, coiled tubing or sucker pump rods. A drillstem sampler is also available. Downhole fluid samples can be transferred to the sample cylinder on site without the use of mercury.

Features

- Shortest sampler of its kind available in the market

- Confirmed sample volume (600 cm³)

- Ability to operate in hostile well conditions

- Positive displacement operation

- No risk of contamination prior to or after sampling

- Adjustable sampling duration

- Mercury-free transfer to shipping bottle

- Positive locking after tool closure

- Ability to validate sample in sample chamber

| Volume: | 600 cm³ |

| Max. operating pressure: | 15,000 psi (1,035 bar) |

| Test pressure: | 22,500 psi (1,550 bar) |

| Max. operating temperature: | 360 °F (180 °C) |

| Length: | 11.45 ft (3,491 mm) |

| Diameter: | 1-11/16“ (43 mm) |

| Weight: | 55 lbs (25 kg) |

| Top connection: | 15/16-10 UN |

| Material: | Seamless Stainless Steel according to NACE MR-01-75 Bronze Alloy |